Cement Mill Capacity Calculation Formula

Cement Mill Capacity Calculation Formula; ... been made to optimize PID controllers of cement milling. The process . between the input signal u1 and the process ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Cement Mill Capacity Calculation Formula; ... been made to optimize PID controllers of cement milling. The process . between the input signal u1 and the process ...

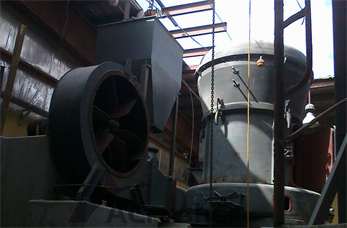

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL 3. ... the most essential engineering formulas used in the cement manufacturing process. All formulas are .

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

Epoxy Granite Filling an Industrial Hobbies RF45 Mill for Vibration Dampening and Rigidity. Filling the machine castings with Epoxy Granite (sometimes ...

Use of the Bogue calculation to determine the clinker mineral content of Portland cement.

CEMENT MILL FORMULAS MILL CRITICAL VELOCITY ... been made to optimize PID controllers of cement milling. The process simulation is . between the input signal u1 ...

Cedar Siding milled to order delivered to your jobsite. Cedar siding prices and pictures, grade descriptions and pattern diagrams. National and International Delivery.

Brazilian Journal of Chemical Engineering ... Optimizing the control system of cement milling: process modeling and controller tuning based on loop ... the formula α ...

How to Make Sugar Rockets. Sugar rockets sound innocuous, but they produce thrust that can lift them hundreds of meters in the air. This wikiHow will show you how to ...

Cement Mill Charging Formula. cement mill charging formula mill charge load calculation 19 ... Process Crusher . Cement Mill Grinding Media Charging Chart 1 .

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

THE MANUFACTURING PROCESS Portland cement is made by heating raw ... Chemical formula ... IXMaterialsBCement5 together into a mill where the rock is .

Cement Process . Get Price. about cement mill formulas ... CEMENT MILL FORMULAS MILL cement as well as ensuring high mill .Figure 6b equation of the (RDF) ...

A few short notes on aspects of basic chemistry, of particular relevance to cement.

cement plant calculation. Grinding ball mill load calculation formula ... It is India''s first split location dry process cement plant with Fuller.

Two of the most commonly specified requirements for concrete used in the manufactured concrete products industry are the design compressive strength (f'' c) and the ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Densities of common products in both Imperial and SIunits

Resources include AIA contract documents, handbooks, guidelines, and MasterSpec.

Chapter 80 Rubber Industry GENERAL PROFILE. Louis S. Beliczky and John Fajen. There are two basic types of rubber used in the rubber industry: natural and synthetic.

Best Practices Guide to Wall Siding, Trim, Finishes on Building Exteriors, includes the following topics: Water leakage through building exteriors, cause, cure ...

The process is divided in 3 parts: Raw Mill ... the most essential engineering formulas used in the cement manufacturing process. All formulas are presented in ...

Kirloskar Electric Company goes way beyond Kirloskar Electric is wellknown for creating unique solutions for customized applications related to industrial power and ...

Contents ONET Job Description Occupational Information Network

WhatsApp)

WhatsApp)